Introduction

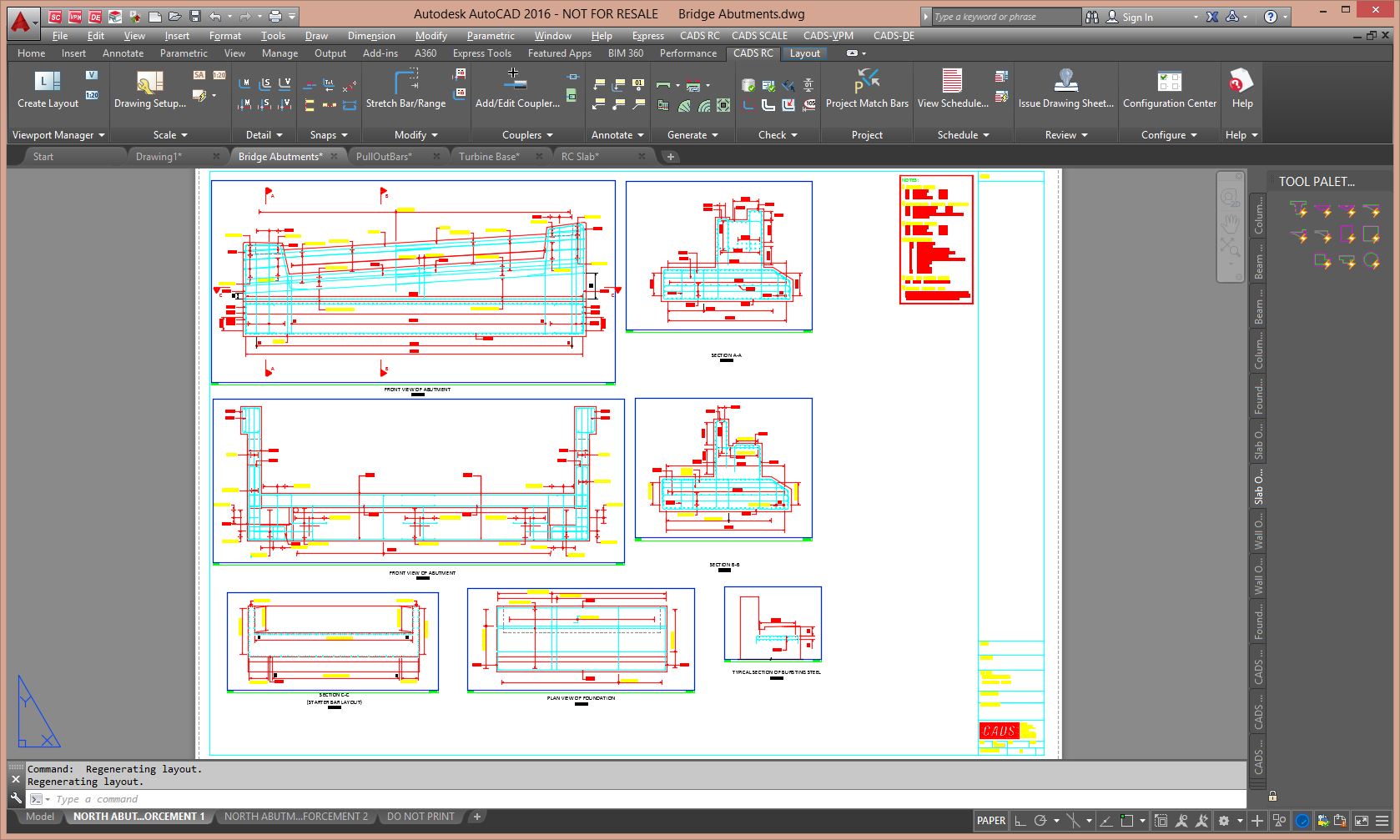

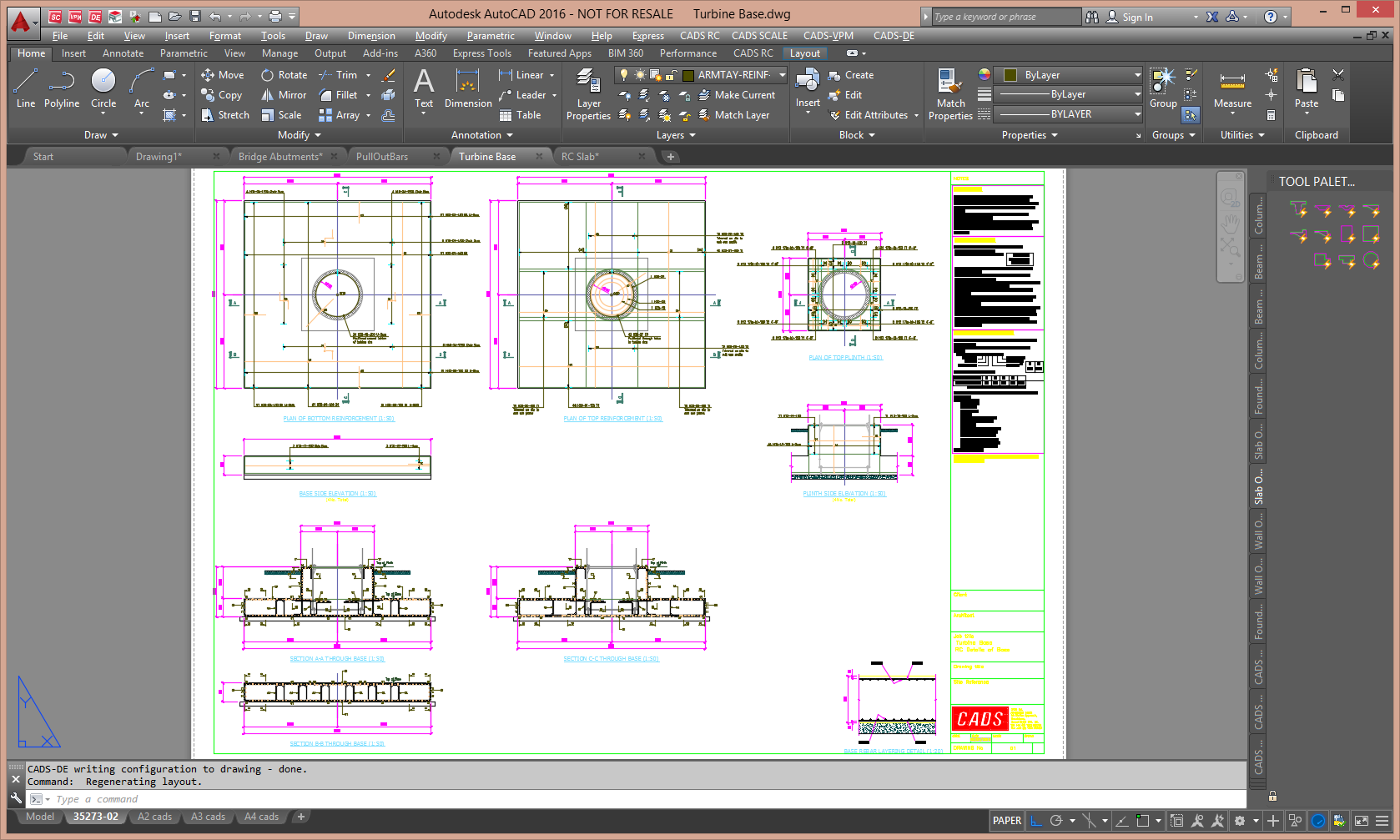

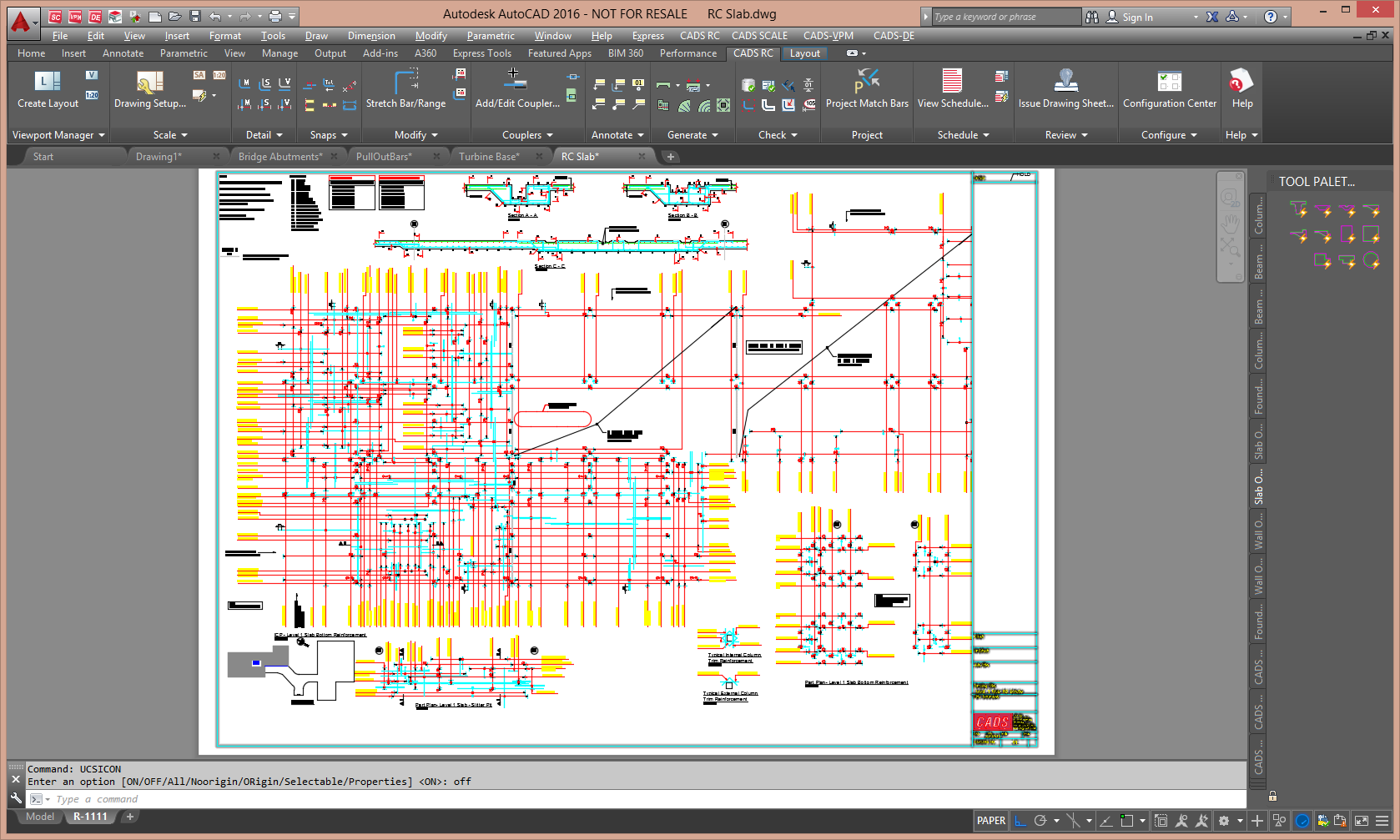

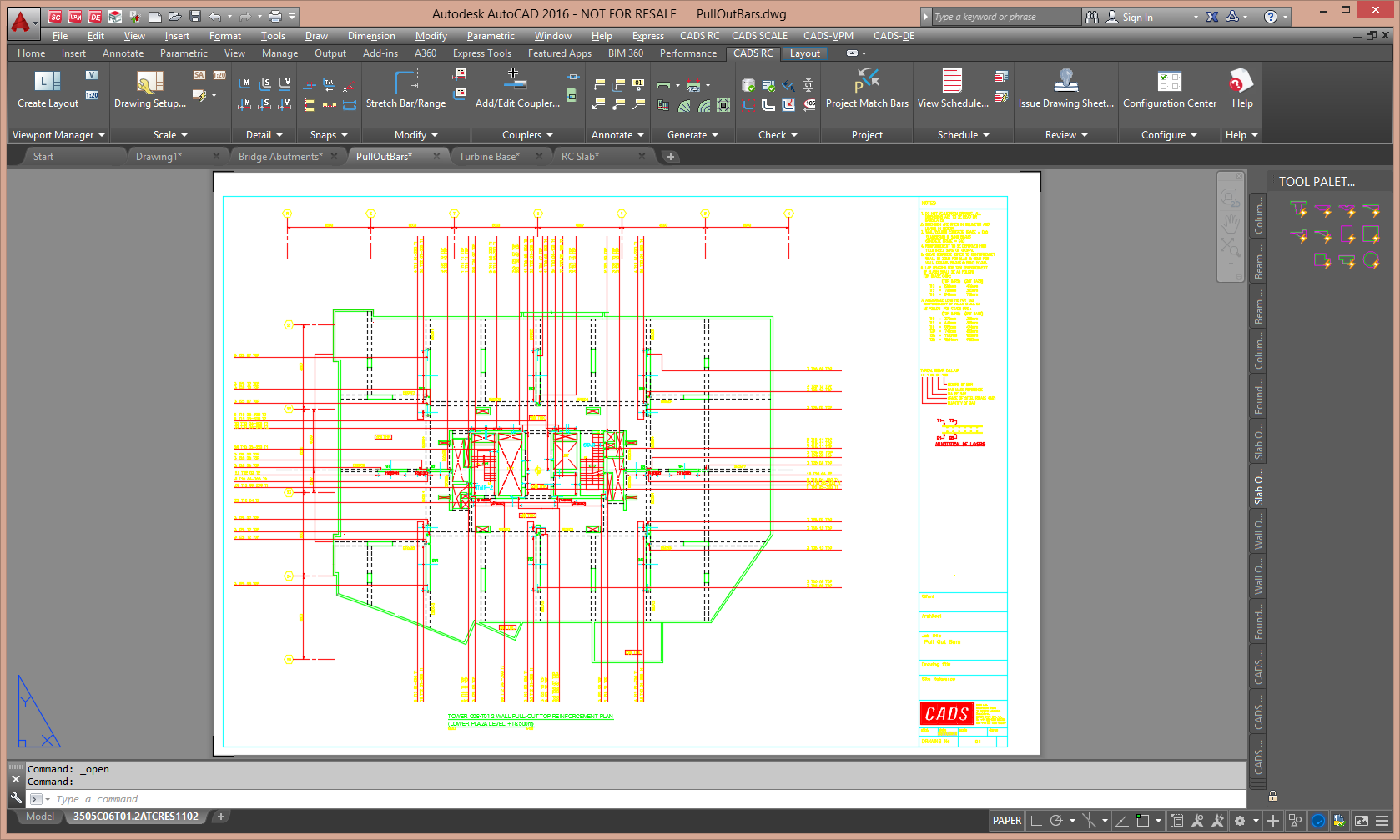

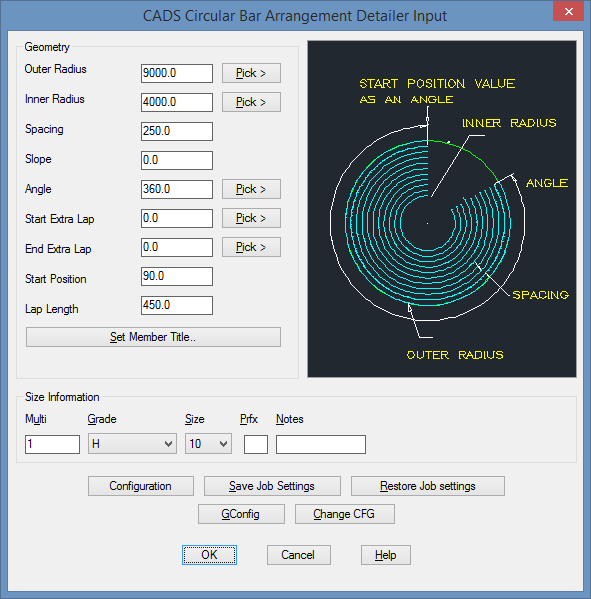

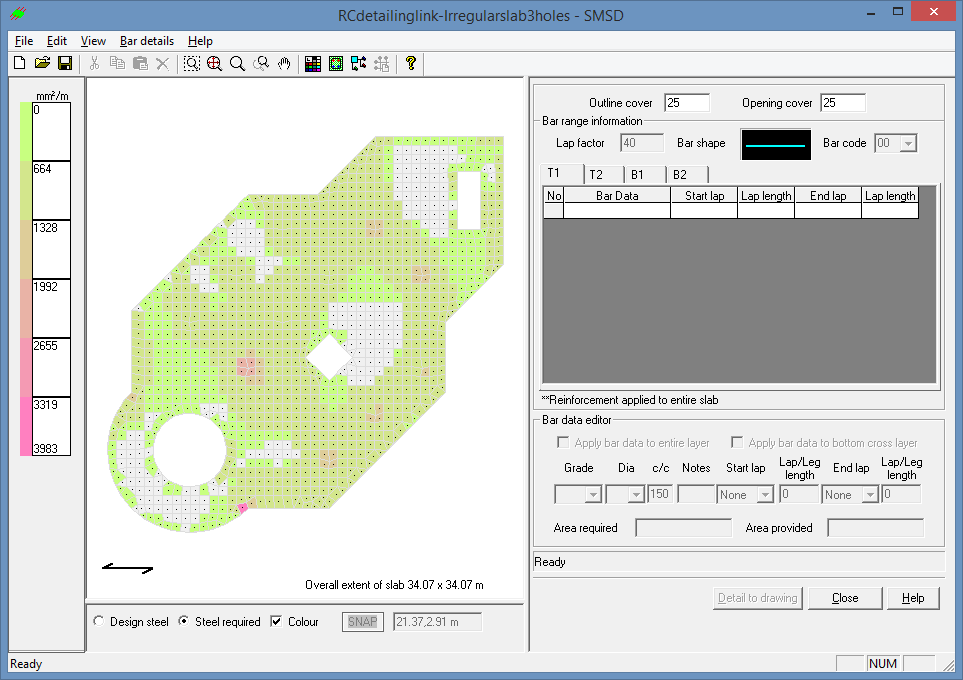

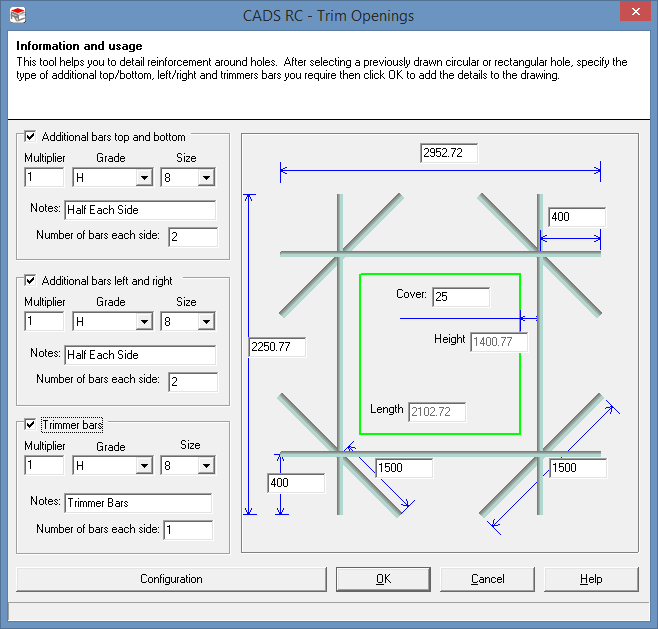

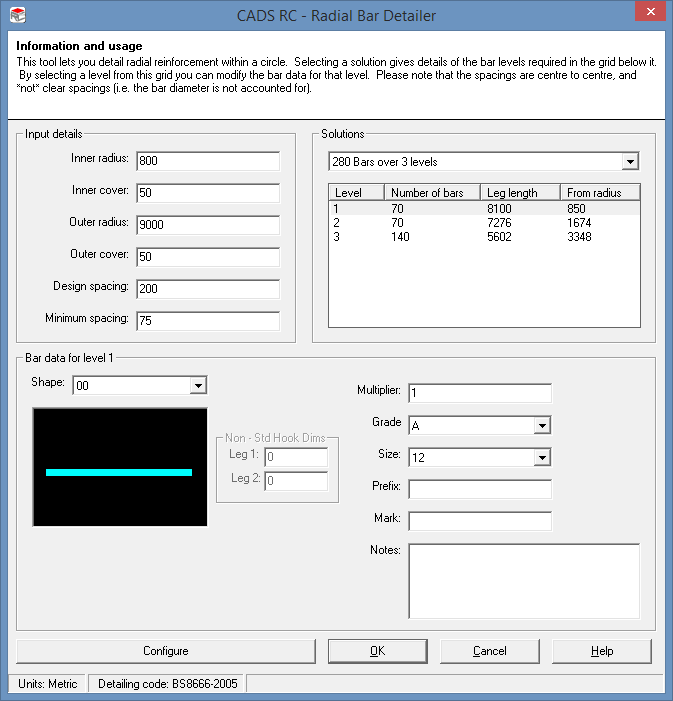

CADS has established an enviable reputation for providing expertise as well as expert software for reinforced concrete detailers. Running in AutoCAD, CADS RC has been the market leading reinforced concrete detailing software in the UK and around the world for more than 20 years. CADS RC’s success is due to its advanced detailing features and technical excellence, which include integration with design and fabrication software. The automatic bar bending schedule is updated in real time which means errors are eliminated and time is saved. CADS RC can detail anything and has been successfully used on all sorts of building, transportation, water, process and power projects including precast concrete elements.

Key Features

AutoCAD

CADS RC builds on AutoCAD, the industry standard CAD platform. It fully exploits the stable 2D drawing environment of AutoCAD, tailoring a solution for rebar detailing and bar bending scheduling that meets the stringent requirements of the industry. As an integrated AutoCAD application, CADS RC adds functionality and toolbars to your AutoCAD system and is supported by quality user manuals and training.

If you are a CAD Manager you will find it easy to recruit trained and experienced technicians for such an industry standard solution, whilst the level of support, advice and expertise available through our help desk will impress all users.

Global codes

CADS RC is a global player in the truest sense of the word. Since the original software was launched as CADS RC in the UK over 20 years ago, further versions for North America, India and South Africa have been released. High quality output, stability, integration and flexibility have seen the adoption of CADS RC across diverse worldwide markets. CADS RC is often the default choice for many international and prestige projects, the software having earned its’ reliability and consistency credentials.

Quality

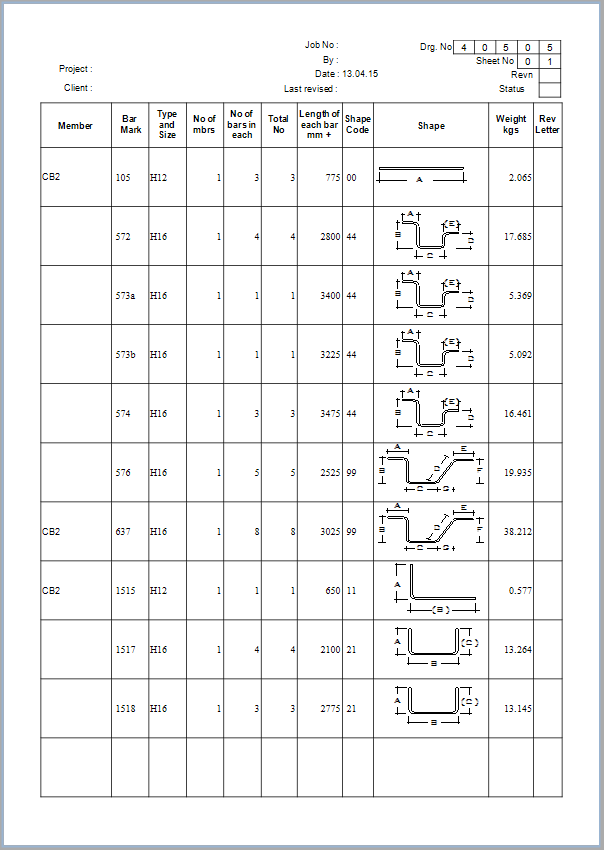

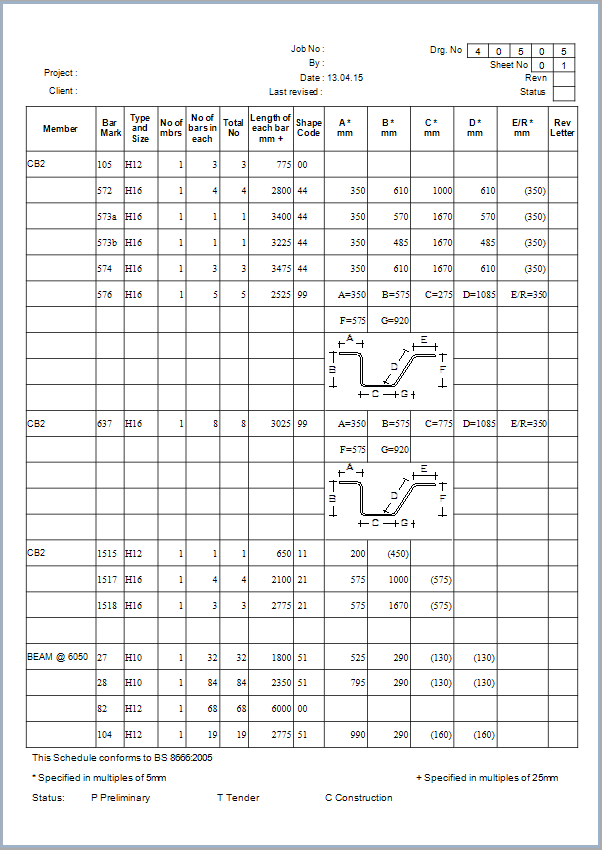

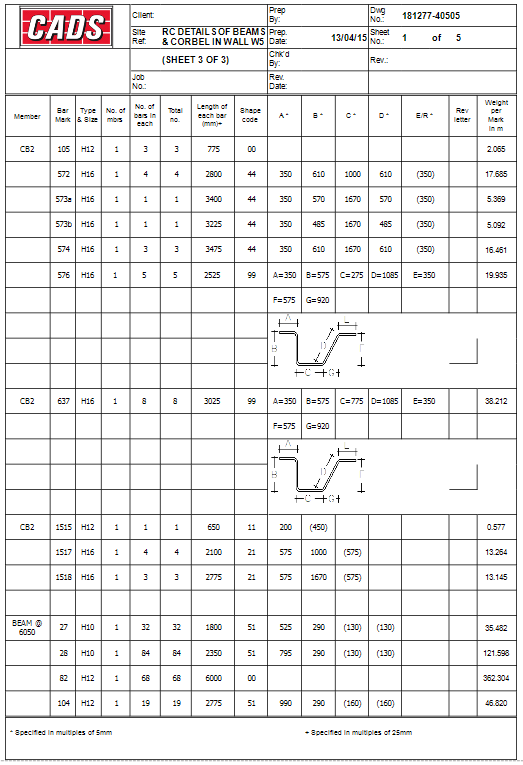

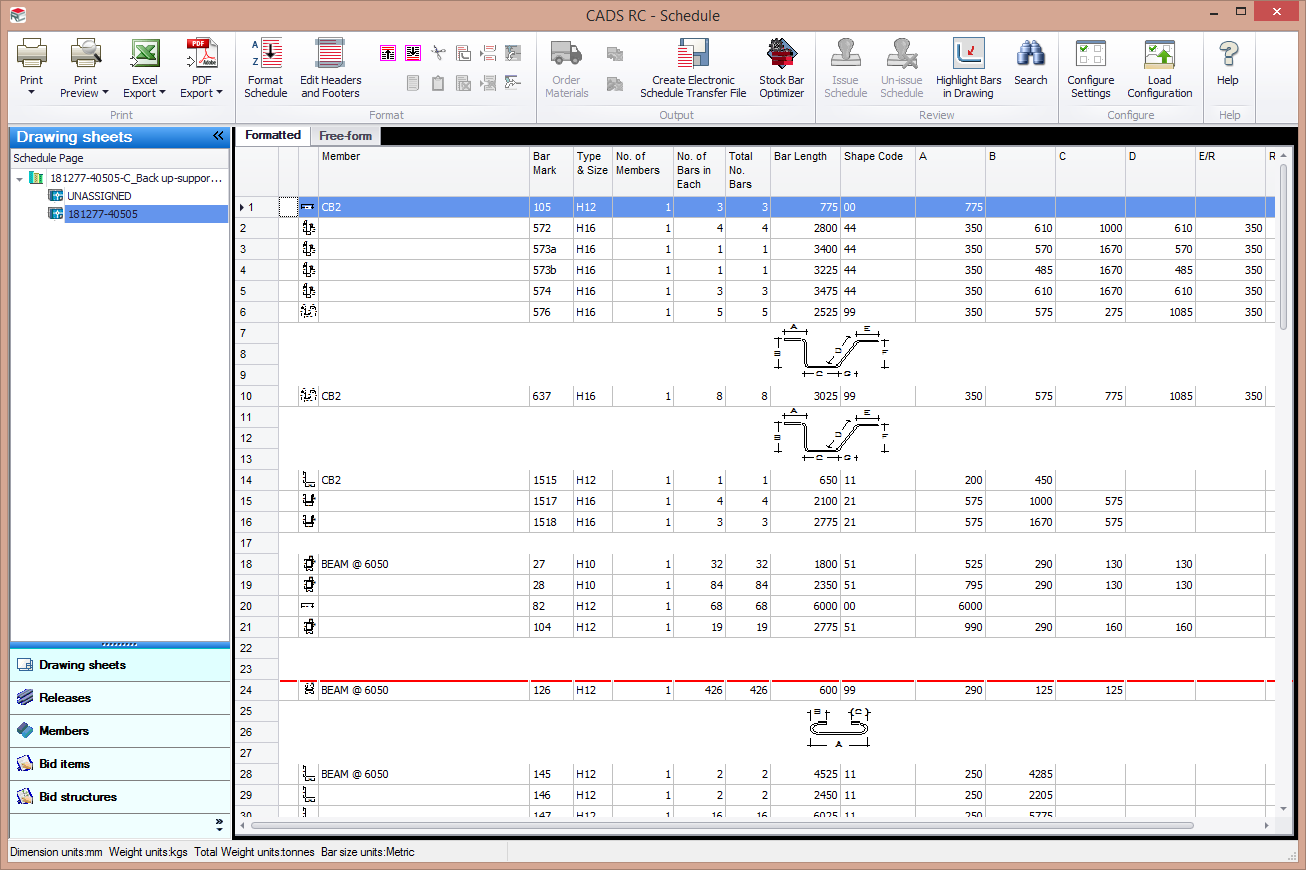

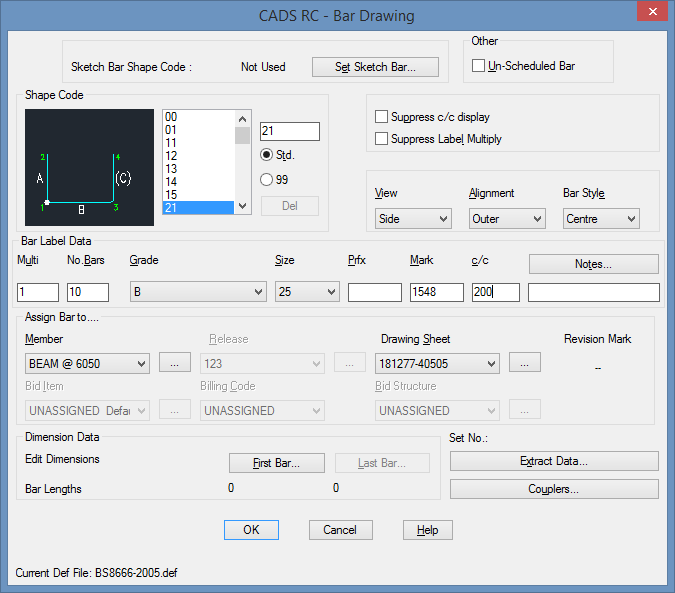

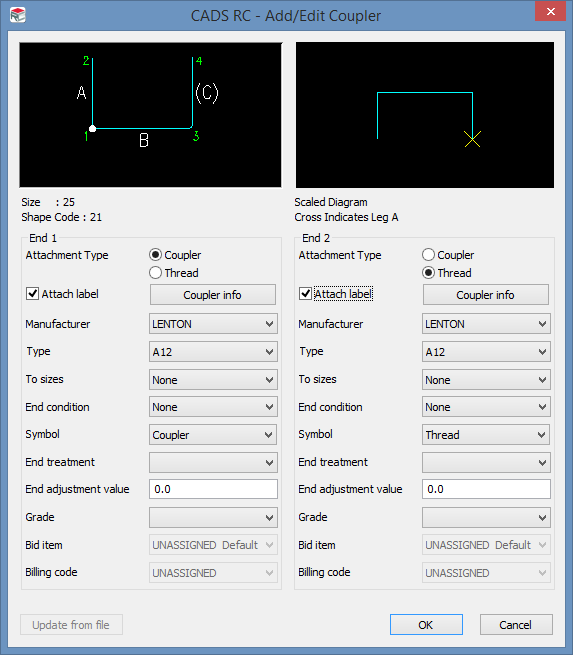

CADS RC maintains a reinforcement database that always reflects exactly what is on the drawing. In addition, all new bars and changes are instantly added to the bar bending schedule which means that checking is reduced and errors virtually eliminated. Additional audit commands detect incomplete or unlabelled bars and ensure compliance with the configured detailing standard. CADS RC drawings require less manual checking, thus scheduling errors are virtually a thing of the past!

Savings

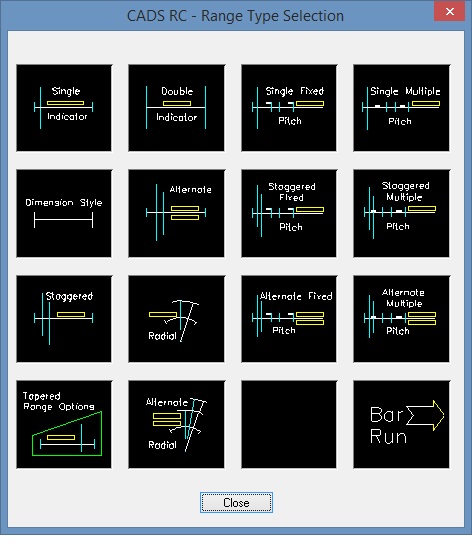

Rebar detailing can be a slow manual process, with no certainty as to the accuracy or consistency of the eventual drawing output. Scrap and wastage due to inaccurate reinforcement drawings, mistakes in Bar Bending Schedules (BBS) and unutilised off-cuts costs the construction industry. Reinforcement detailing and bar listing has never been easier. CADS RC helps you accomplish this faster and more accurately than manual methods by creating drawings whilst automating the preparation of BBS.